ROAM Magnesium Alloys

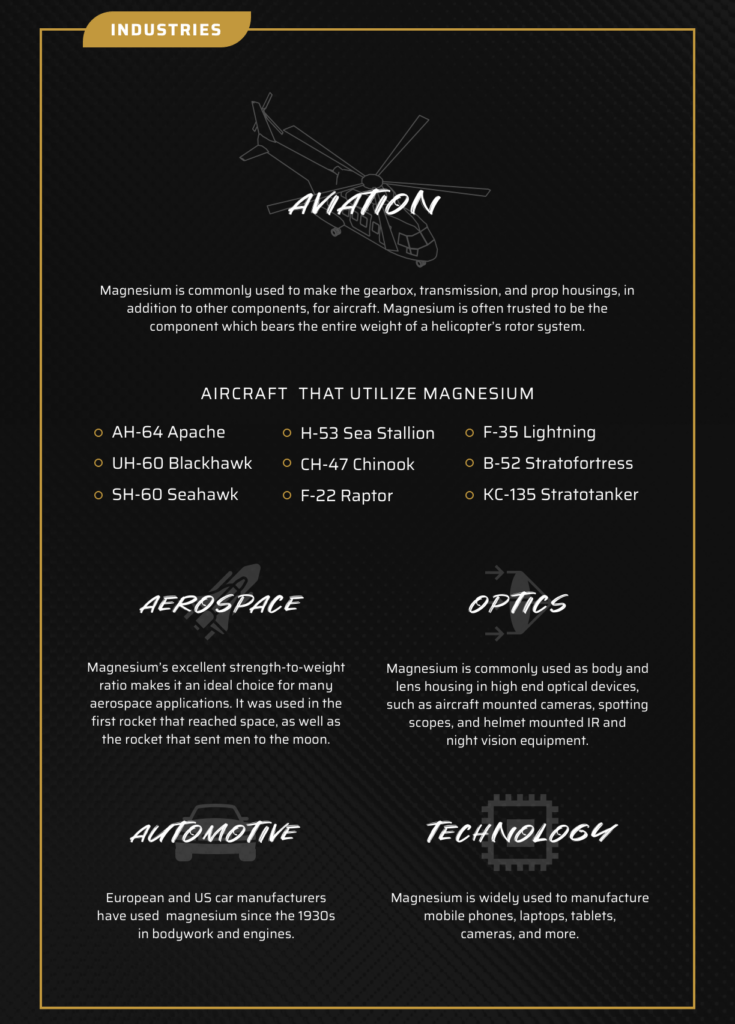

An alloy is the mixture of a metal with other periodic elements. These various materials possess unique characteristics, making them appropriate for different applications. We at ROAM have exhaustively researched, tested, and sourced the appropriate alloys for this unique application. ROAM magnesium possesses strength and hardness properties that are either comparable to or exceed 6061 aluminum.

The few other examples of magnesium used in the firearms industry have all been alloys AZ31B and AZ61. These are some of the most widely used alloys of magnesium. They are easily formable, easily sourced, and cheap, but they are not the proper materials for such a demanding application. Simply put, they are not strong or hard enough; Roam Magnesium is.

How Flammable is Magnesium?

Citation: The above video was created by DOW Chemical Company in the 1950’s. It’s current ownership and copyright are unknown.

Addressing Corrosion

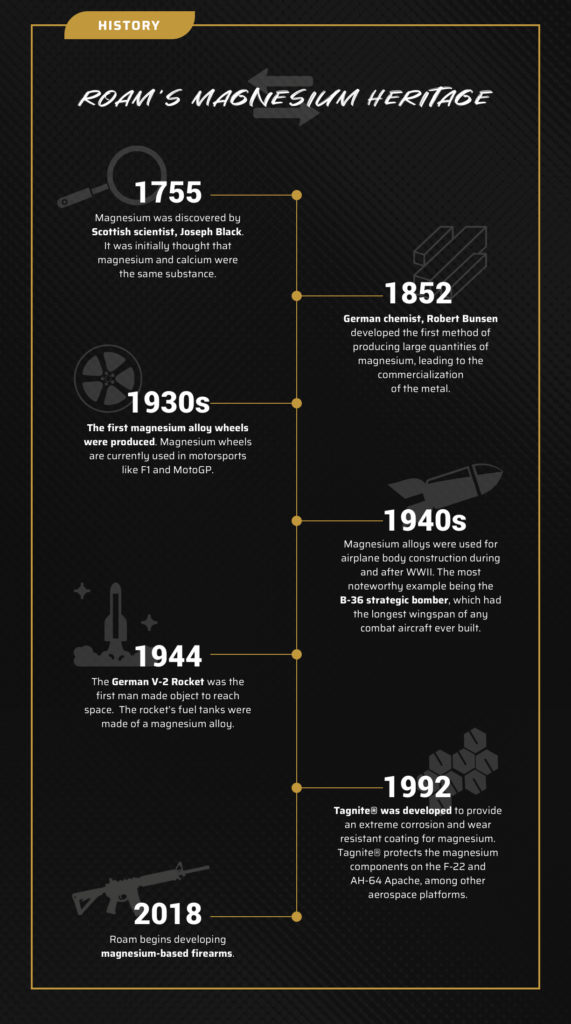

Corrosion is the process of a metal gradually oxidizing. To many people, the most recognizable form of this process is steel rusting. The iron atoms in the steel combine with oxygen in the presence of moisture. Through this process, a metal gradually loses its mass. Most magnesium alloys are effected by this process to a heightened degree, making corrosion protection critically important. Roam has partnered with Technology Applications Group, Inc. to utilize the most corrosion and wear resistant magnesium coating in the world, Tagnite® anodize. In addition to the anodize, a topcoat of Cerakote® is applied to our firearms.

Year Long Corrosion Test

We often get asked about the long-term durability and corrosion resistance of our magnesium parts. We can provide plenty of technical data about how durable Tagnite® and Cerakote® are but sometimes you just need more real-world proof. So that’s what we did.

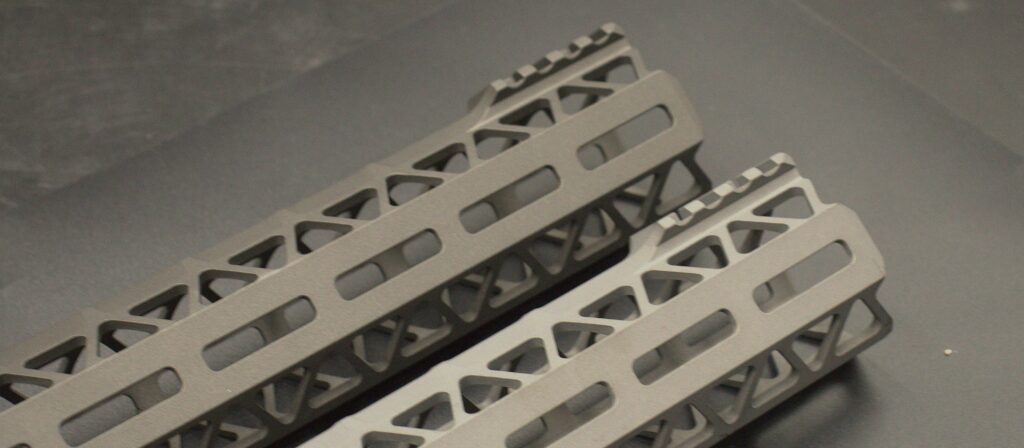

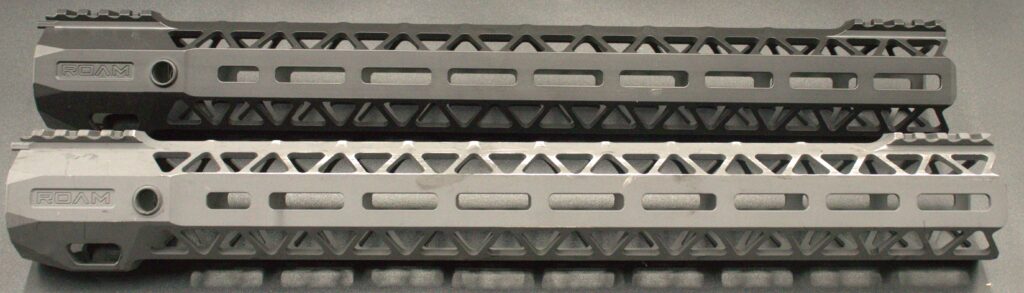

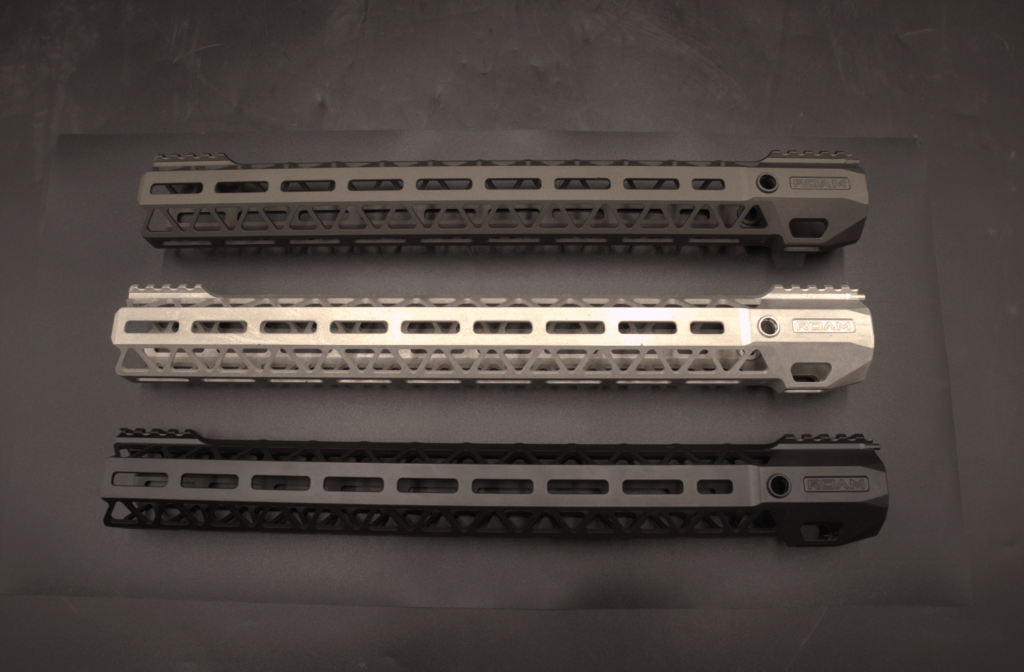

To validate the performance of our corrosion-resistant and durable coatings, we conducted a year-long outdoor exposure test in Grand Forks, North Dakota a region known for its extreme weather conditions. Three magnesium handguards were tested: one left as raw magnesium, one treated with Tagnite® anodize Cerakote® roughed up with some sandpaper to simulate heavy use over a long period of time, and one finished with both Tagnite® and a Cerakote® left in pristine condition as if would ship form us to you.

Grand Forks sees hot, humid summers and brutally cold winters, with strong winds and long stretches of sun or darkness depending on the season. Despite these harsh conditions, the three handguards held up exceptionally well over the course of a year. They endured extreme heat, freezing temperatures, and everything in between without showing signs of corrosion or structural damage—only getting dirty from regular exposure. This test proves that with normal use and routine cleaning, Roam’s magnesium components remain tough, reliable, and built to last.

Week 52

You must be logged in to post a comment.